Retro sneakersTitle: "Putian Shoes' No. 1 Vulnerability: Easy Glue Separation"

Retro sneakersTitle: "Putian Shoes' No. 1 Vulnerability: Easy Glue Separation",

The Issue of Easy De-lamination in Putian Shoe Airway No. 1

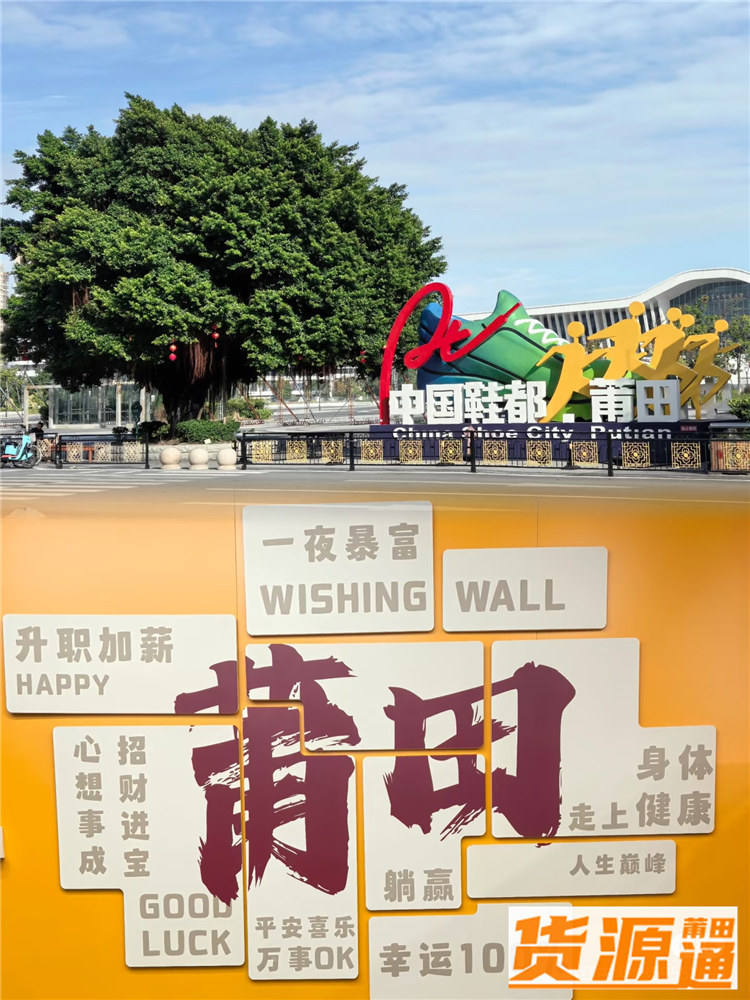

Putian, a region renowned for its footwear industry, has long been a hub for the production of various shoe designs and styles. However, one common issue that many consumers have encountered with the locally produced shoes, particularly the Airway No. 1 model, is the tendency to develop cracks or de-lamination easily. This problem has been a subject of concern for both users and industry insiders.

The Nature of De-lamination in Putian Shoes

De-lamination, commonly known as ‘opening of the glue joint’, refers to the phenomenon where the layers of material in a shoe begin to separate from each other due to poor quality control during manufacturing. In the case of Putian Shoe Airway No. 1, this issue often arises due to the use of inferior quality materials or inadequate bonding techniques during production.

Multiple factors can contribute to the occurrence of de-lamination in these shoes. The use of substandard adhesives or improper application of glue during assembly can result in weak joints that are prone to separation under regular wear and tear. Additionally, the quality of the materials used in the manufacturing process, such as synthetic leather or rubber compounds, may not be up to the mark, leading to premature deterioration of the shoe’s structural integrity.

Another aspect that cannot be overlooked is the impact of climate and environmental conditions on the durability of shoes. Exposure to extreme temperatures, humidity, or other weather elements can affect the adhesives used in the manufacturing process, leading to early failure and de-lamination. This becomes especially concerning for users who live in areas with varied weather conditions.

The issue of de-lamination not only affects the aesthetic appeal of the shoes but also their performance and longevity. When the layers of a shoe start to separate, it can lead to discomfort while wearing, reduce the support provided, and ultimately result in premature replacement of the footwear.

To address this problem, manufacturers and quality control agencies need to work together to ensure strict oversight over the production process. Implementing proper quality control measures, using high-quality materials, and adopting advanced manufacturing techniques can help reduce the occurrence of de-lamination in Putian shoes. Moreover, providing after-sales support and customer service to address consumer concerns can go a long way in building brand reputation and trust.

In conclusion, while de-lamination remains an issue in Putian Shoe Airway No. 1 and other locally produced footwear, awareness of the problem and efforts towards its resolution can pave the way for improved quality and customer satisfaction in the long run.

- Bootleg sneakersWhere to Buy Authentic Putian Shoes?

- Retro shoesPutian Shoes: Superior Quality First and Second Layer Leather 这个标题符合英文习惯,同时涵盖了莆田鞋和头层皮二层皮这两个关键词,并且没有超过您要求的字符数限制。

- Bootleg sneakersTitle: "Affordable Air Force Ones in Putian - Quality Shoes for a Fraction of the Price"

- Bootleg sneakersTop 10 Pudong Fashion Shoes in Ranking List

- Counterfeit shoesPutian Shoes: Does It Offer High, Medium and Low Quality?

- Replica hype shoesPrice of Putian High-Quality Replica Shoes

- Replica sneakersCost of a Pair of High-Quality Fake Putian Shoes.

- Unauthorized retro sneakersPutian Shoes Barcode Scan Failure: Unable to Identify Item Information